Drum Dryer?

Drum dryers were developed in the early 1900s. They were used in drying almost all liquid food materials before spray drying came into use. Nowadays, drum dryers are used in the food industry for drying a variety of products, such as milk product, baby foods, breakfast cereal, fruit and vegetable pulp, mashed potatoes, cooked starch and spent yeast. Prefer to explore more by phone?

DRUM DRYER PRODUCTS?

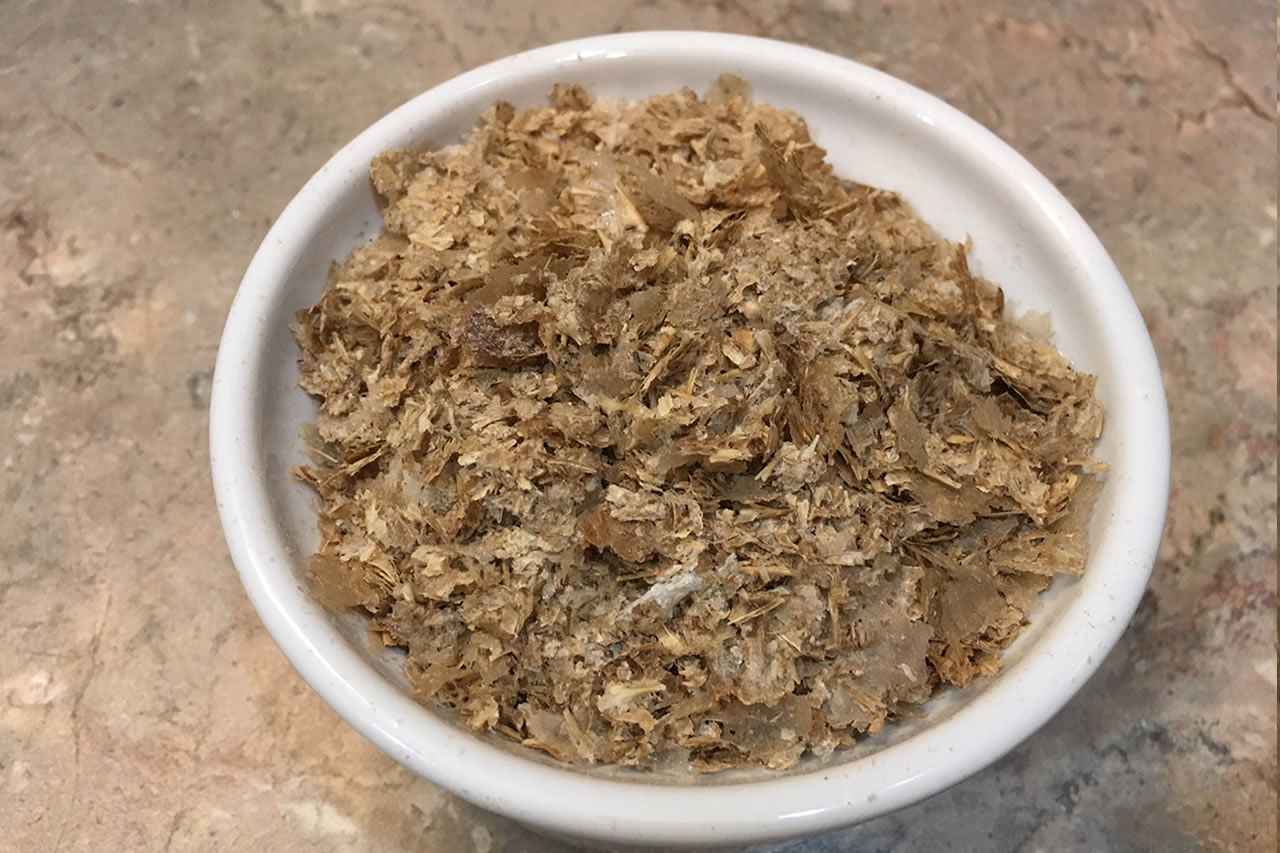

A couple of very well known examples of the type of product produced in this type of machinery is baby cereal in the form of flakes or mashed potatoes in the form of flakes. Drum drying is one of the most energy efficient drying methods, and is particularly effective for drying high viscous liquid or pureed foods..

DRYING OPERATIONS

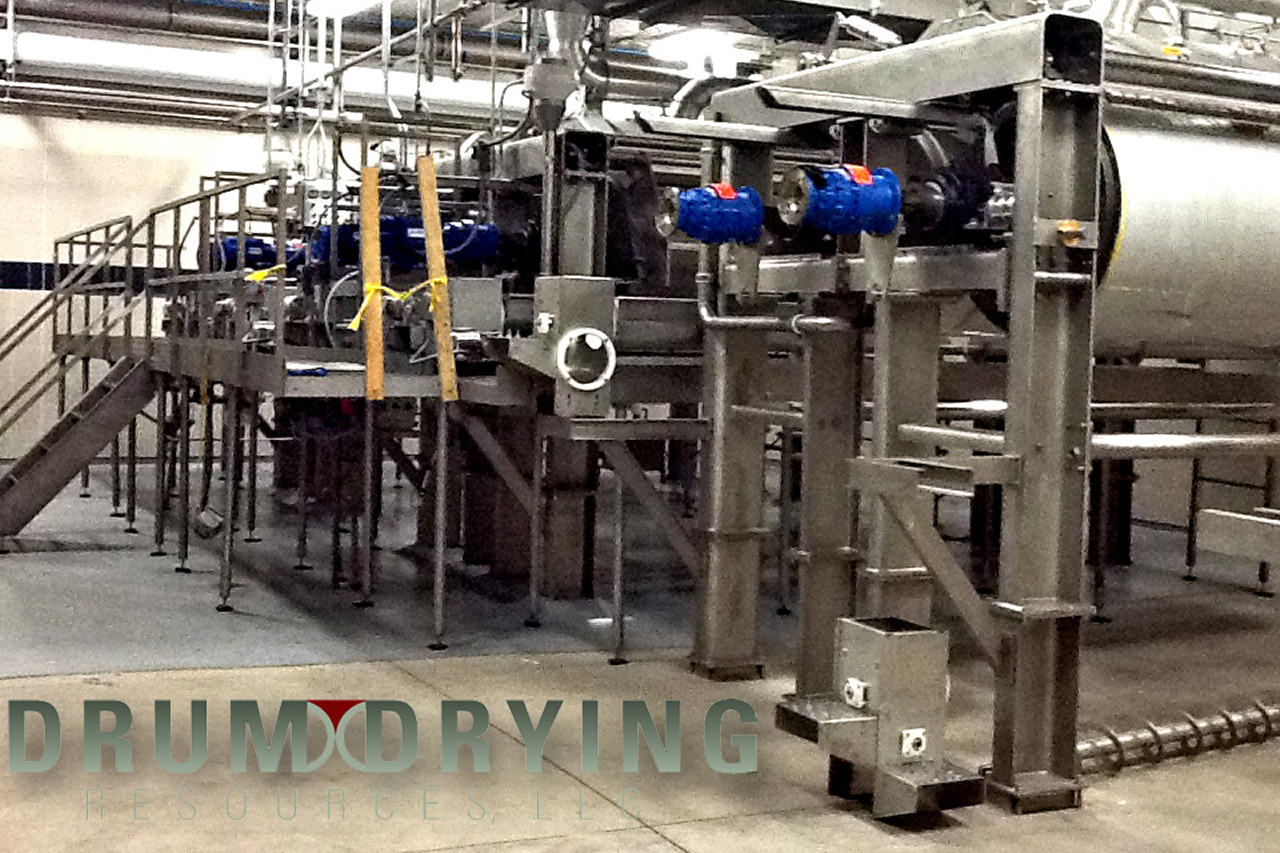

In a drying operation, liquid, slurry, or puree material is applied as a thin layer onto the outer surface of revolving drums that are internally heated by steam. After about three-quarters of a revolution from the point of feeding, the product is dried and removed with a static scraper. The dry product is collected and is transferred (usually pneumatically) to a rotary hammer mill, reduced to the desired particle size and packaged. In order to ensure that the product is consistent and that it meets customer specifications, a delicate balance between feed rate, roll speed, steam pressure and roll gap must be achieved.

THE SYSTEM

In a drying operation, liquid, slurry, or puree material is applied as a thin layer onto the outer surface of revolving drums that are internally heated by steam. After about three-quarters of a revolution from the point of feeding, the product is dried and removed with a static scraper. The dry product is collected and is transferred (usually pneumatically) to a rotary hammer mill, reduced to the desired particle size and packaged. In order to ensure that the product is consistent and that it meets customer specifications, a delicate balance between feed rate, roll speed, steam pressure and roll gap must be achieved.

ADVANTAGES

- Products have good porosity and hence good rehydration due to boiling evaporation.

- Drum dryers can dry very viscous foods, such as pastes and gelatinized or cooked starch, which cannot be easily dried with other methods.

- Drum dryers normally have high energy efficiency

- Drum drying can be clean and hygienic.

- Drum dryers are easy to operate and maintain.

- The dryers are flexible and suitable for multiple but small quantity production

CHALLENGES

- Some products may not form a good film on the drum surface and are not suitable for drum drying.

- Some products, especially those with high sugar contents may not be easily scrapped off from the drum.

- Relatively low throughput, compared to spray drying. However, the initial investment is much lower.

- High cost of changing the drum surface because of the precision machining that is required.

- Possible scorching of the product, which could impact the cooked flavor and off-color due to direct contact with the high temperature drum surface.Not able to process salty or other corrosive materials due to potential pitting of the drum surface.